GLX

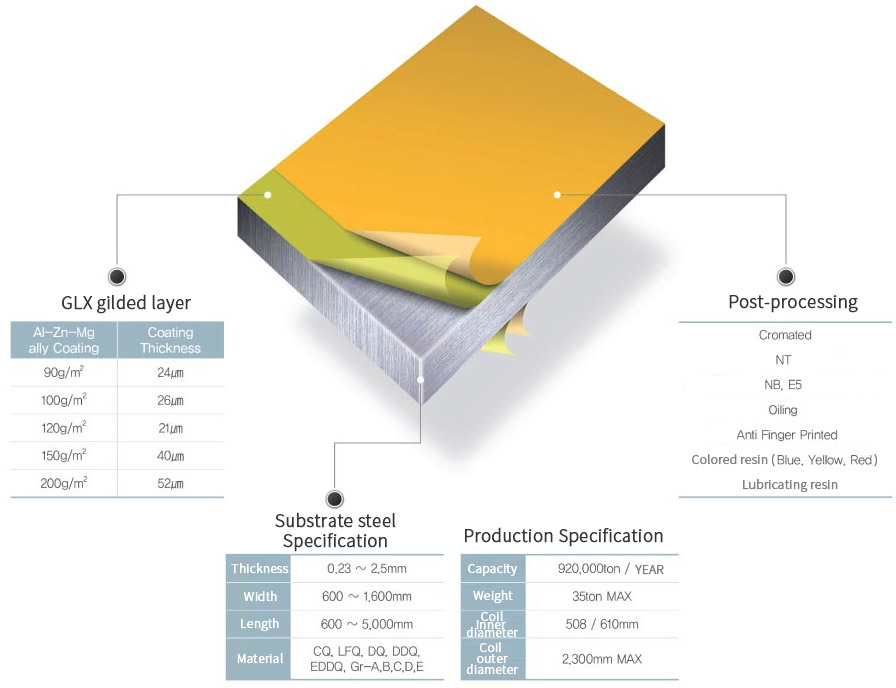

GLX Coating Steel sheet (GLX)

It is produced by alloying aluminum, zinc, silicone and magnesium then, hot dipping it on a steel sheet. It is designed to be suitable for applications requiring high corrosion resistance. The gilded layer of GLX consists of 55% of aluminum(AI), 43.3% of zinc(Zn) and magnesium and 1.6% of silicon(Si). The alloy plating process of GLX is supreme plating technique among all mass produced hot dipped steel plates worldwide so, in recognition of its uniqueness, it have been patented in Australia, China, Taiwan and Korea.

Schematic image

Characteristics

- Corrosion resistance

With effects from magnesium and aluminum alloy, it provides excellent corrosion resistance not only on gilded surfaces but also on scratched and cutting parts those of being generated during bending process and site installation maintaining stabilized condition of self-sacrificial corrosion of zinc. . - Heat resistance

It has excellent heat resistance. It is attributed from high content of aluminum (80% of surface volume) of a gilded layer and it is ideal for applications requiring high temperature for a long period of time such as automotive mufflers or electric oven. - Heat reflexibility

It has more than twice heat reflectivity than general galvanized steel sheets. From this characteristic, it can save energy for cooling, etc. by using it as roofing and walls without painting. It can be used to a wide range of applications, such as country houses, warehouses and livestock housing. - Paintability

It has good cohesion between a gilded layer and paint, and is paintable without separate preprocessing. From this characteristic, it shows superior performance compare to general GI and EGI steel sheets when it used for a base plate for painted hot dip steel sheets, such as LUXTEEL for interior and exterior construction materials.

Applications

- Roofing and walls, home appliances parts, auto parts, etc.